Thermoelectric coolers

MD02 Series of Single TE Modules

-

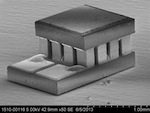

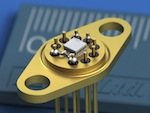

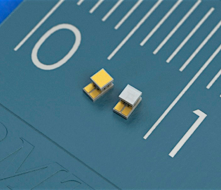

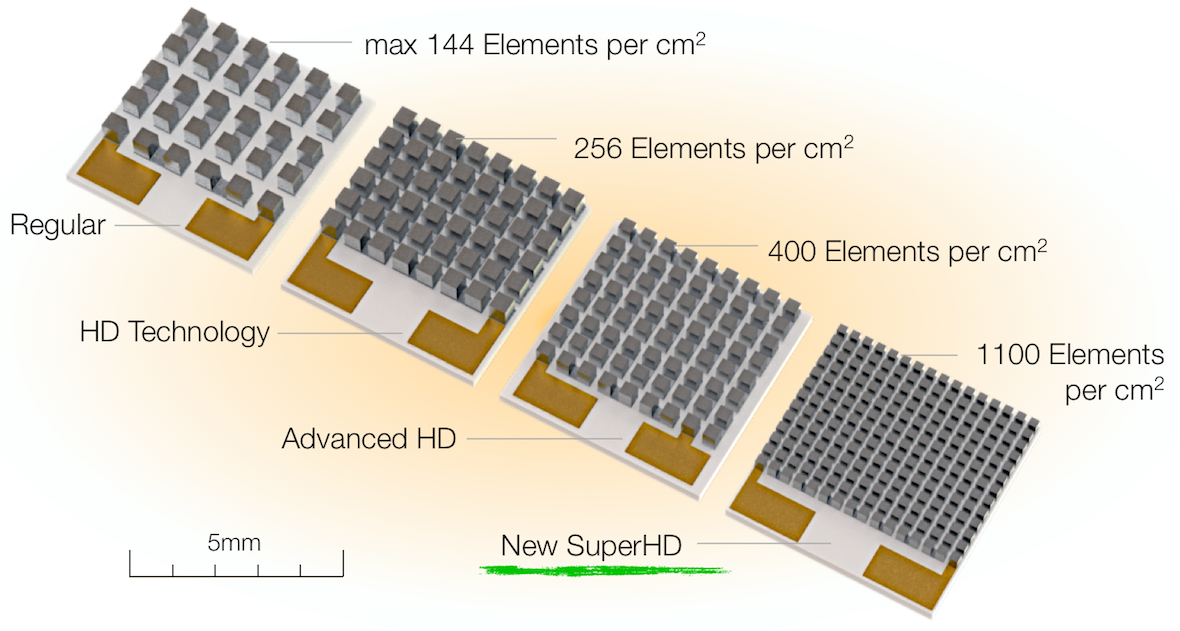

The MD02 Series consists of thermoelectric cooler based on RMT SuperHD pellets placement technology. MD02 thermoelectric coolers have a unique combination of internal elements tiny cross-section and less than 100um distance between them. It allows to fit more than 1100 elements per cm2 pellets. The result is - miniature thermoelectric coolers wit low current, low power consumption and operating voltage, optimal for the best power supply efficiency. MD02 thermoelectric coolers have operating voltage optimal for the best DC-DC converters efficiency, or even allow to skip DC-DC converter in power supply. MD02 Series thermoelectric coolers are optimal for telecom transceivers with active temperature stabilization (for example TO-can TOSA), VCSELs and miniature LD applications in small form factor (TO-46/TO-56 headers). Al2O3 ceramics is applied by default, AlN ceramics is available as an option.

MD02 TECs are developed by RMT mainly for telecom industry. MD02 thermoelectric coolers have low operating current and low power consumption. The variety of dimensions, performance and current/voltage ratio makes MD02 thermoelectric coolers the optimal choice for temperature stabilization in many telecom applications.

|

Thermoelectric coolers MD02 Series

|

|||

|

Performance table at 27C, vacuum.

|

Performance table at 50C, N2.

|

||

Specifications

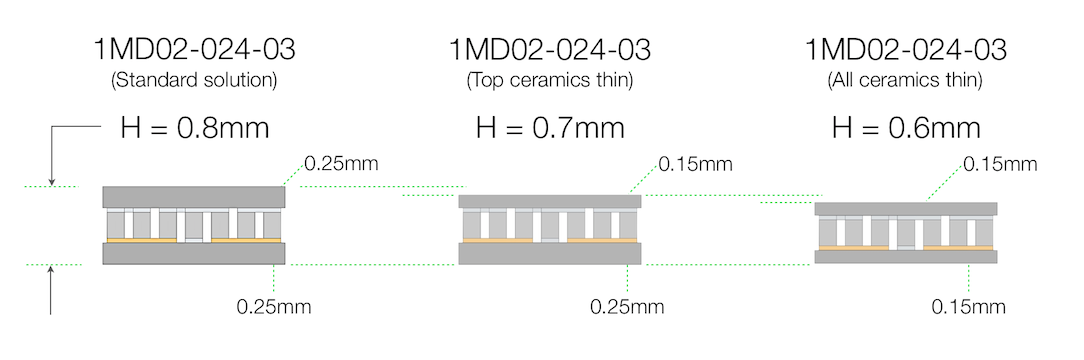

Important Note:MD02 Series TECs are manufactured by default on 0.25mm thickness ceramics. There is also 0.15mm ceramics as a solution for low-height thermoelectric coolers.

Please, use On-Line Assistant to find the most optimal thermoelectric cooler by dimensions and performance parameters. The detailed analysis of TEC performance and power consumption can be made with free TECCad software for Windows or special iTECPad app for iPad (available free on App Store).

Options

Information furnished by RMT Ltd is believed to be reliable. However no responsibility is assumed for possible inaccuracies or omission. Specifications are subject to change whithout notice.