Thermoelectric coolers

Thermoelectric coolers with hole

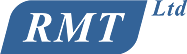

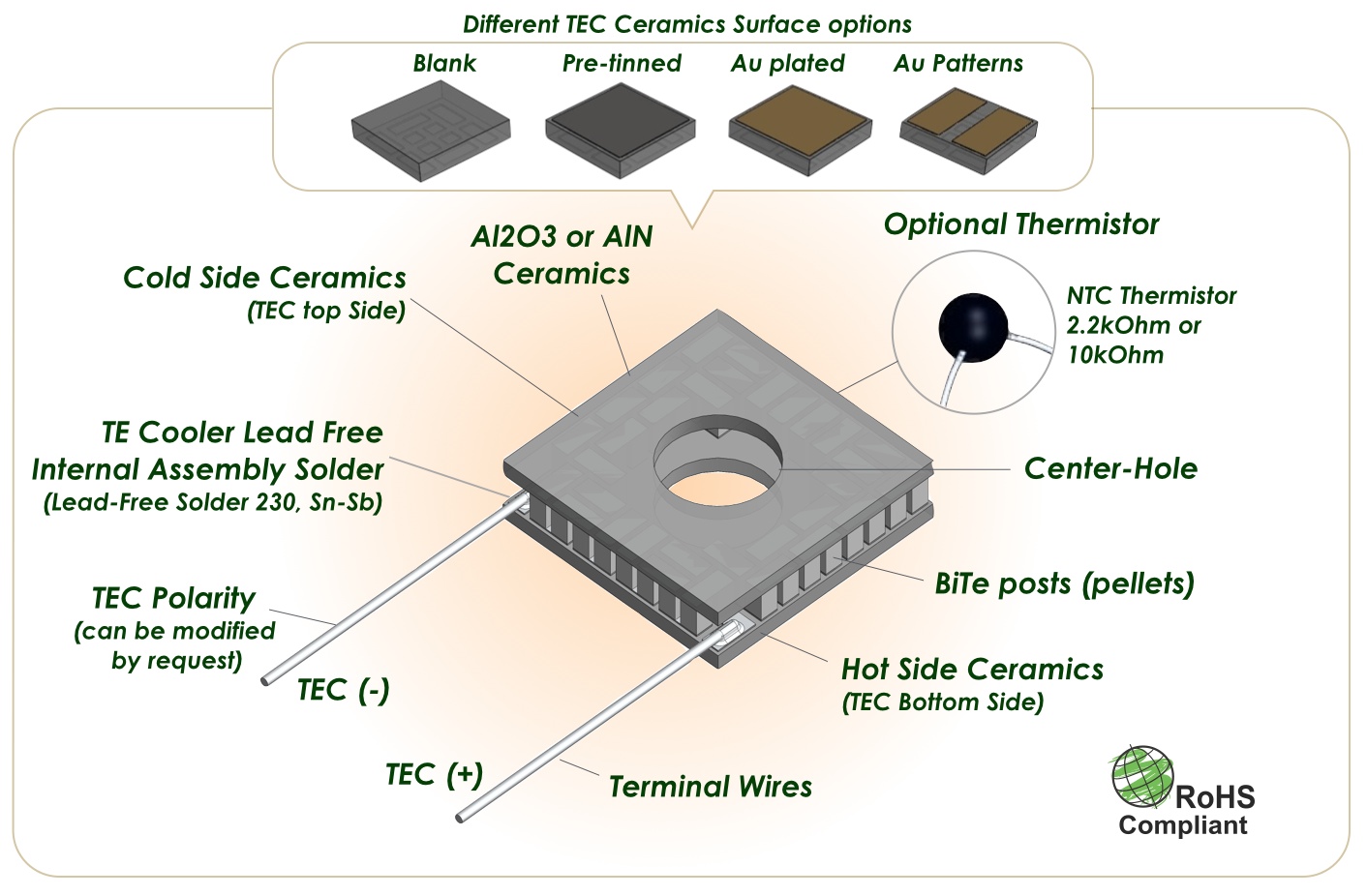

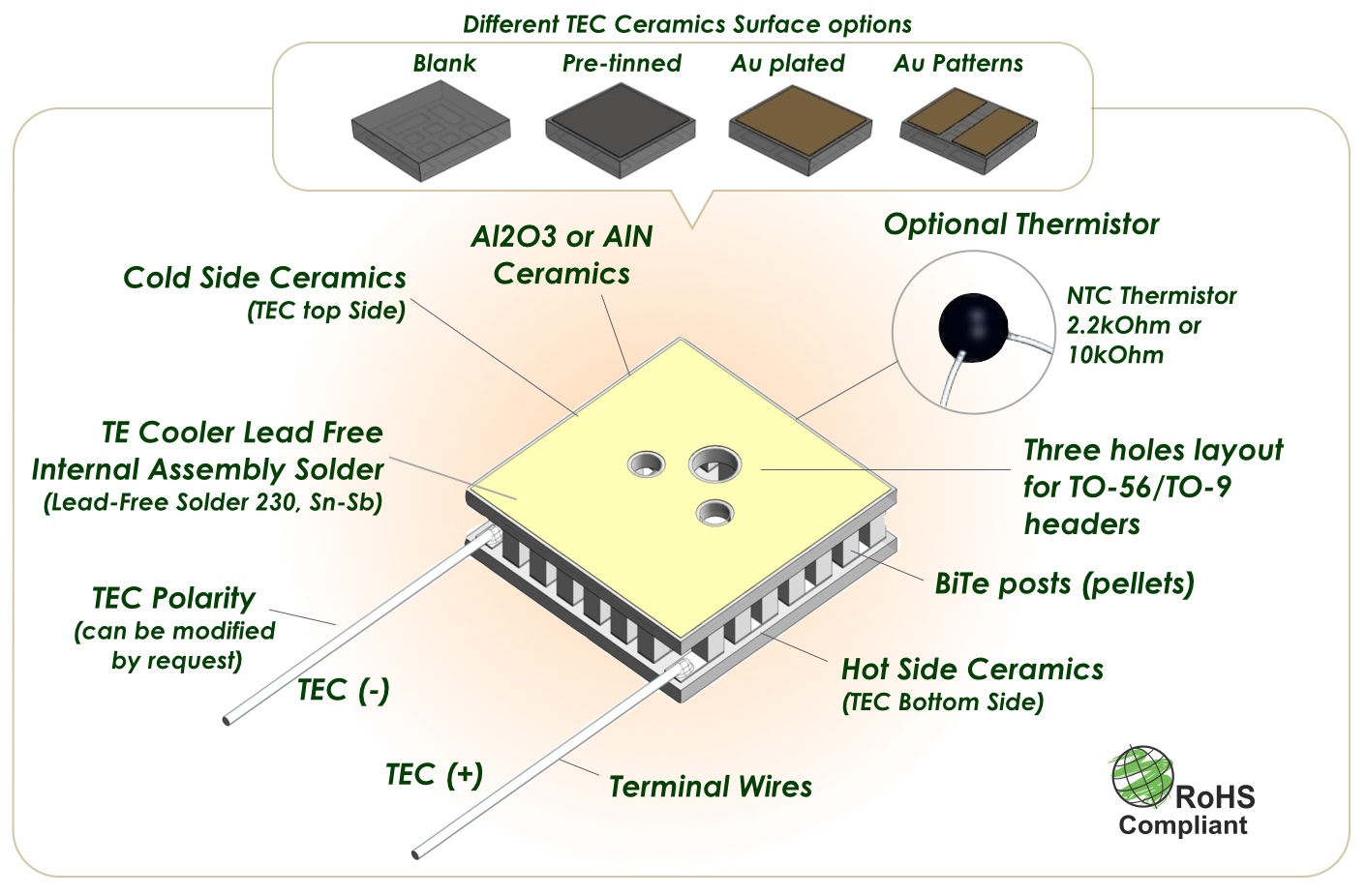

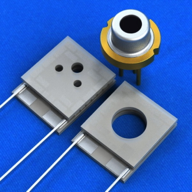

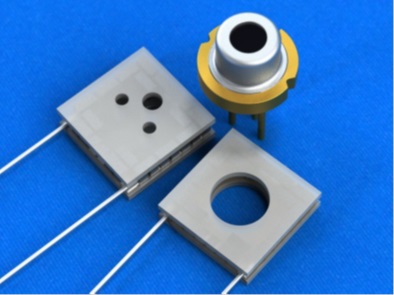

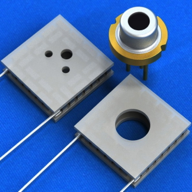

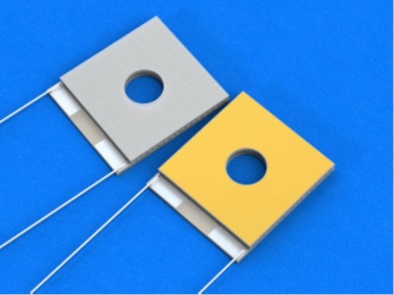

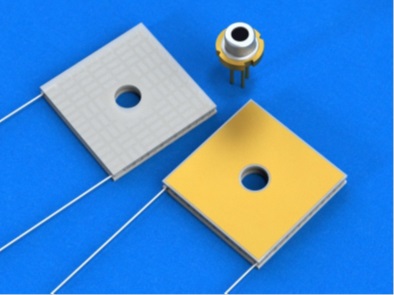

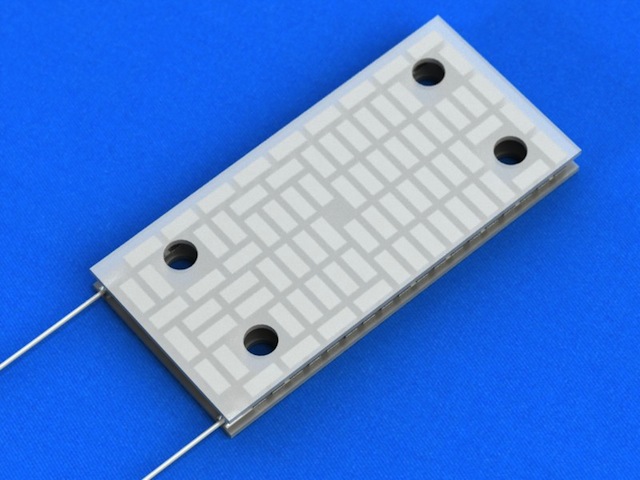

Thermoelectric coolers with holes are used for “external” cooling. Term “external cooling” means TEC attached to the entire assembly on a header, rather than to a heat-generating object. There are two typical cases where thermoelectric coolers with holes can be used: 1) powerful LD on TO-38/46/56/9 type headers with not enough space to mount TEC on a header, 2) already sealed (un-cooled) devices, where the advanced temperature stabilization gives additional benefits in terms of laser wavelength stability, optical power, device lifetime or sensitivity.

In case of “external” cooling the entire sealed assembly on a header is being mounted on TEC with a hole to put the pins through. The TEC then is installed on an appropriate heatsink. The “external” cooling is a good solution to implement advanced temperature stabilization in applications with sealed devices.

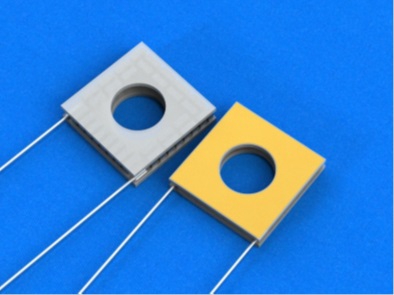

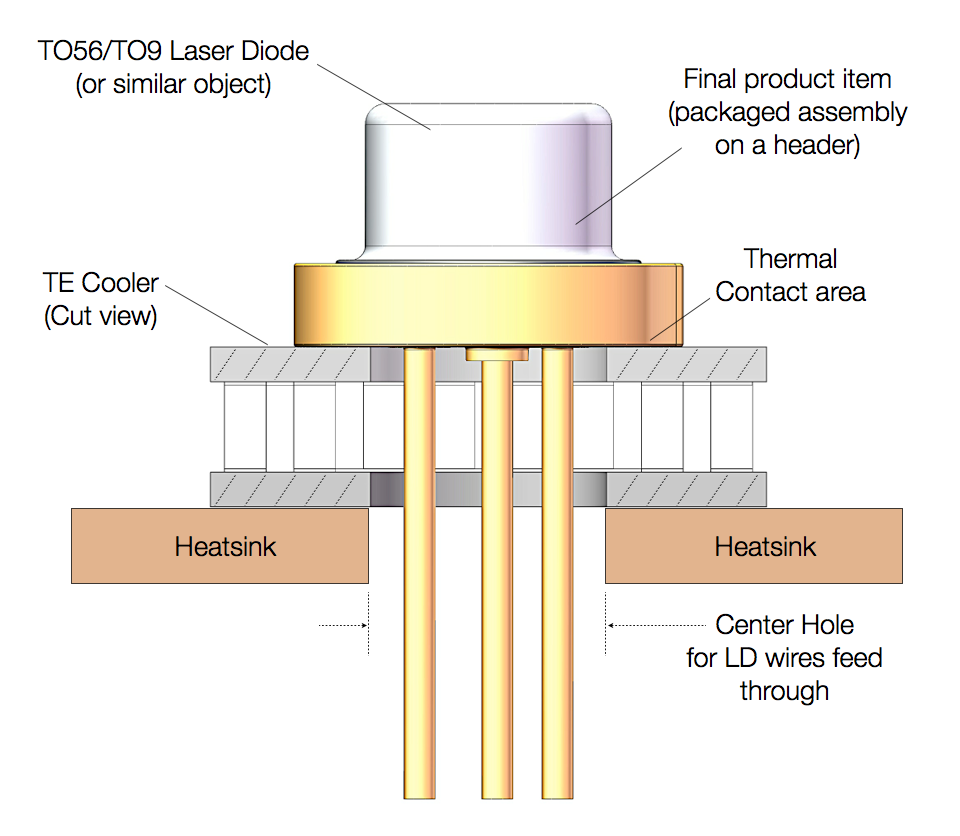

Thermoelectric coolers with holes are also ideal for various testing equipment, LD calibration tools, optoelectronics components setup instruments, quality control and environmental testing, temperature cycling devices and similar applications. RMT and TEC Microsystems provide the complete flexibility with holes modification, layout customization and development of special thermoelectric coolers with holes for specific applications. The list of standard solutions is specified below.

|  |

| Fig 2 - Flexibility with

holes modifications | |

| |

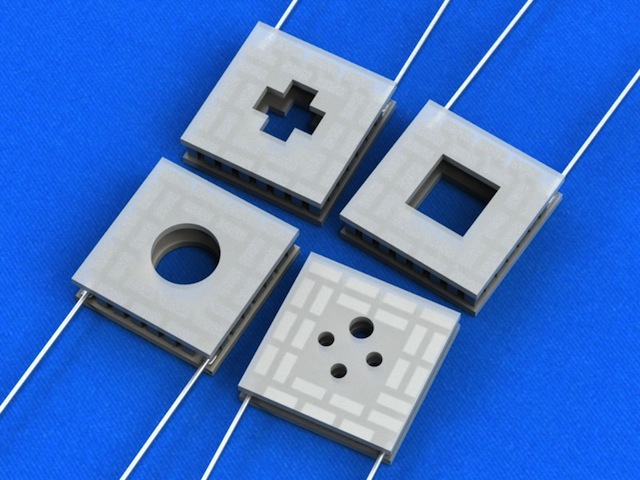

| Fig 1 - External and internal cooling methods (click to zoom) | Fig 3 - Customized TEC for external

cooing of regular 14-pin “Butterfly” LD package |

Specifications

|

Exterior |

Type |

Performance @27℃ Vacuum |

Performance @50℃ Dry N2 |

Dimensions |

DataSheet |

||||||||||||

|

dTmax K |

Qmax W |

Imax A |

Umax V |

ACR Ohm |

dTmax K |

Qmax W |

Imax A |

Umax V |

ACR Ohm |

A mm |

B mm |

C mm |

D mm |

H mm |

|||

|

1MD06-015-03H (3.4mm dia Apperture) |

|||||||||||||||||

|

|

1MD06-015-03H |

68 |

5.7 |

5.2 |

1.9 |

0.3 |

72 |

6.3 |

5.1 |

2.0 |

0.30 |

6.6 |

6.6 |

6.6 |

8.0 |

1.4 |

|

|

1MD06-015-xxH (3.4mm dia Apperture) |

|||||||||||||||||

|

|

1MD06-015-05H |

70 |

3.7 |

3.2 |

1.9 |

0.4 |

74 |

4.0 |

3.2 |

2.1 |

0.5 |

6.6 |

6.6 |

6.6 |

6.6 |

1.6 |

|

|

1MD06-015-08H |

72 |

2.4 |

2.1 |

0.7 |

74 |

2.6 |

2.1 |

0.8 |

1.9 |

||||||||

|

1MD06-015-10H |

72 |

1.9 |

1.7 |

0.8 |

74 |

2.1 |

1.7 |

1.0 |

2.1 |

||||||||

|

1MD06-015-12H |

72 |

1.6 |

1.4 |

1.0 |

74 |

1.8 |

1.4 |

1.1 |

2.3 |

||||||||

|

1MD06-015-15H |

73 |

1.3 |

1.1 |

1.3 |

73 |

1.4 |

1.1 |

1.4 |

2.6 |

||||||||

|

1MC06-024-xxH (3.4mm dia Apperture) |

|||||||||||||||||

|

|

1MC06-024-05H |

70 |

5.8 |

3.2 |

3.0 |

0.7 |

74 |

6.3 |

3.2 |

3.3 |

0.8 |

8.0 |

8.0 |

8.0 |

8.0 |

1.6 |

|

|

1MC06-024-08H |

72 |

3.8 |

2.1 |

1.1 |

75 |

4.1 |

2.1 |

1.2 |

1.9 |

||||||||

|

1MC06-024-10H |

72 |

3.1 |

1.7 |

1.3 |

75 |

3.4 |

1.7 |

1.5 |

2.1 |

||||||||

|

1MC06-024-12H |

72 |

2.6 |

1.4 |

1.6 |

74 |

2.9 |

1.4 |

1.8 |

2.3 |

||||||||

|

1MC06-024-15H |

73 |

2.1 |

1.1 |

2.0 |

74 |

2.3 |

1.1 |

2.3 |

2.6 |

||||||||

|

1MD06-032-03H (3.4mm dia Apperture) |

|||||||||||||||||

|

|

1MD06-032-03H |

67 |

11.7 |

5.1 |

3.9 |

0.6 |

72 |

12.8 |

5.0 |

4.3 |

0.64 |

8.0 |

8.0 |

8.0 |

9.4 |

1.4 |

|

|

1MD06-032-xxH (3.4mm dia Apperture) |

|||||||||||||||||

|

|

1MD06-032-05H |

70 |

7.6 |

3.2 |

4.0 |

0.9 |

75 |

8.2 |

3.1 |

4.4 |

1.0 |

8.0 |

8.0 |

8.0 |

8.0 |

1.6 |

|

|

1MD06-032-08H |

71 |

5.0 |

2.1 |

1.4 |

76 |

5.4 |

2.0 |

1.6 |

1.9 |

||||||||

|

1MD06-032-10H |

72 |

4.1 |

1.7 |

1.8 |

76 |

4.4 |

1.6 |

2.0 |

2.1 |

||||||||

|

1MD06-032-12H |

72 |

3.4 |

1.4 |

2.1 |

76 |

3.7 |

1.4 |

2.4 |

2.3 |

||||||||

|

1MD06-032-15H |

73 |

2.8 |

1.1 |

2.7 |

76 |

3.0 |

1.1 |

3.0 |

2.6 |

||||||||

|

1MC06-030-xxH (5.0mm dia Apperture) |

|||||||||||||||||

|

|

1MC06-030-05H |

71 |

7.4 |

3.2 |

3.8 |

0.9 |

74 |

8.1 |

3.2 |

4.2 |

1.0 |

10.0 |

10.0 |

10.0 |

10.0 |

1.6 |

|

|

1MC06-030-08H |

72 |

4.8 |

2.1 |

1.4 |

74 |

5.3 |

2.1 |

1.5 |

1.9 |

||||||||

|

1MC06-030-10H |

72 |

3.9 |

1.7 |

1.7 |

74 |

4.3 |

1.7 |

1.9 |

2.1 |

||||||||

|

1MC06-030-12H |

73 |

3.3 |

1.4 |

2.0 |

74 |

3.6 |

1.4 |

2.3 |

2.3 |

||||||||

|

1MC06-030-15H |

73 |

2.6 |

1.1 |

2.5 |

73 |

2.9 |

1.1 |

2.8 |

2.6 |

||||||||

|

1MC06-039-xxH (6.7mm dia Apperture) |

|||||||||||||||||

|

|

1MC06-039-05H |

71 |

9.6 |

3.3 |

4.9 |

1.1 |

73 |

10.6 |

3.2 |

5.4 |

1.3 |

12.0 |

12.0 |

12.0 |

12.0 |

1.6 |

|

|

1MC06-039-08H |

72 |

6.3 |

2.1 |

1.8 |

74 |

6.9 |

2.1 |

2.0 |

1.9 |

||||||||

|

1MC06-039-10H |

72 |

5.1 |

1.7 |

2.2 |

74 |

5.6 |

1.7 |

2.5 |

2.1 |

||||||||

|

1MC06-039-12H |

73 |

4.3 |

1.4 |

2.6 |

73 |

4.7 |

1.4 |

2.9 |

2.3 |

||||||||

|

1MC06-039-15H |

73 |

3.4 |

1.1 |

3.3 |

73 |

3.8 |

1.1 |

3.7 |

2.6 |

||||||||

|

1MD06-130-xxH (4.7mm dia Apperture) |

|||||||||||||||||

|

|

1MD06-130-03H |

69 |

52.8 |

5.3 |

16.3 |

2.3 |

76 |

57.8 |

5.3 |

18.0 |

2.6 |

14.4 |

14.4 |

14.4 |

16.4 |

1.4 |

|

|

1MD06-130-05H |

72 |

33.1 |

3.3 |

16.3 |

3.7 |

78 |

36.1 |

3.2 |

18.1 |

4.2 |

1.6 |

||||||

|

1MD06-130-08H |

73 |

21.2 |

2.1 |

16.4 |

5.9 |

79 |

23.1 |

2.1 |

18.1 |

6.6 |

1.9 |

||||||

|

1MD06-130-10H |

73 |

17.1 |

1.7 |

16.4 |

7.3 |

79 |

18.7 |

1.7 |

18.1 |

8.2 |

2.1 |

||||||

|

1MD06-130-12H |

73 |

14.3 |

1.4 |

16.4 |

8.7 |

79 |

15.7 |

1.4 |

18.1 |

9.8 |

2.3 |

||||||

|

1MD06-130-15H |

74 |

11.5 |

1.1 |

16.3 |

10.9 |

78 |

12.6 |

1.1 |

18.1 |

12.2 |

2.6 |

||||||

|

1MC06-098-xxH (3.2mm dia Apperture) |

|||||||||||||||||

|

|

1MC06-098-05H |

72 |

25.2 |

3.3 |

12.3 |

2.8 |

77 |

27.6 |

3.3 |

13.6 |

3.1 |

15.0 |

15.0 |

15.0 |

15.0 |

1.6 |

|

|

1MC06-098-08H |

73 |

16.1 |

2.1 |

12.3 |

4.4 |

77 |

17.6 |

2.1 |

13.7 |

5.0 |

1.9 |

||||||

|

1MC06-098-10H |

73 |

13.0 |

1.7 |

12.3 |

5.5 |

77 |

14.2 |

1.7 |

13.7 |

6.2 |

2.1 |

||||||

|

1MC06-098-12H |

73 |

10.9 |

1.4 |

12.4 |

6.6 |

77 |

11.9 |

1.4 |

13.7 |

7.4 |

2.3 |

||||||

|

1MC06-098-15H |

74 |

8.7 |

1.1 |

12.4 |

8.2 |

77 |

9.6 |

1.1 |

13.7 |

9.2 |

2.6 |

||||||

|

1MC06-098-03H (3.2mm dia Apperture) |

|||||||||||||||||

|

|

1MC06-098-03H |

70 |

40.6 |

5.4 |

12.3 |

1.7 |

75 |

44.5 |

5.3 |

13.6 |

1.9 |

15.0 |

15.0 |

15.0 |

16.5 |

1.4 |

|

Important Note: thermoelectric cooler can be manufactured on standard 0.5mm and thin 0.25mm ceramics. This adds an additional flexibility to performance and height optimization in a particular application. It is also possible to combine various ceramics thicknesses to achieve the most optimal results for TEC height.

Please, use On-Line Assistant to find the most optimal thermoelectric cooler by dimensions and performance parameters. The detailed analysis of TEC performance and power consumption can be made with free TECCad software for Windows or special iTECPad app for iPad (available free on App Store).

Options

Information furnished by RMT Ltd is believed to be reliable. However no responsibility is assumed for possible inaccuracies or omission. Specifications are subject to change whithout notice.