Thermoelectric coolers

Thermoelectric Cooling Modules

-

-

RMT manufactures a wide range of TE coolers from miniature to high power modules, single stage and multi-stage types, different DC current values, all with unique custom parameter options.

There are more than 1500 standard types of thermoelectric coolers available. Cold sides range from 1 x 1 mm² to 18 x 18 mm², maximum current ranges from 0.2 to 6 Amp, dTmax - from 70°C in single stage up to 130°C in multi-stage configurations (specified at 27°C, vacuum). -

Depending on size and performance all TE coolers are divided into several Series. We recommend the software TECCad for optimal thermoelectric cooler selecting and analysis at different conditions, or our On-Line TEC Select Assistant for fast search and selecting of the type you need for your application. You’re also welcome to contact us – we would be glad to assist you.

|

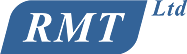

MC04

|

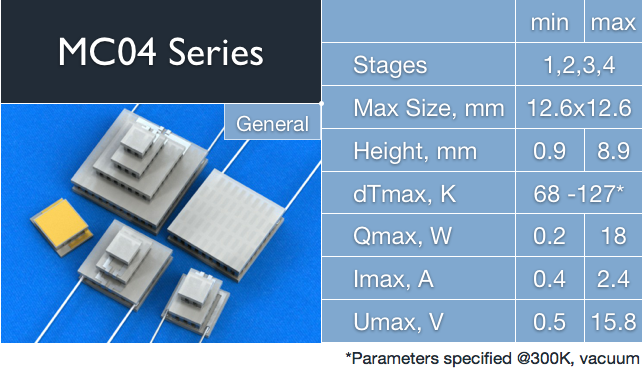

MC06

|

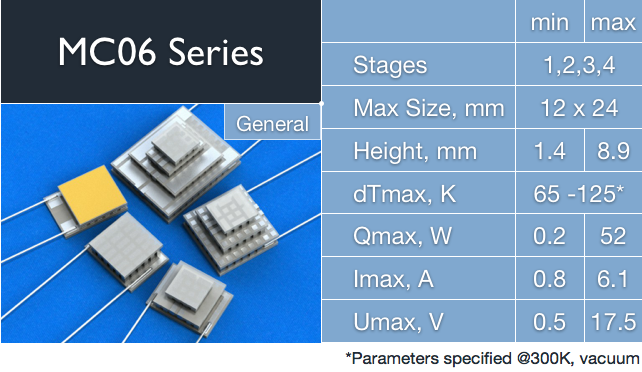

MC10

|

ML06

|

TOSA

|

MD04

|

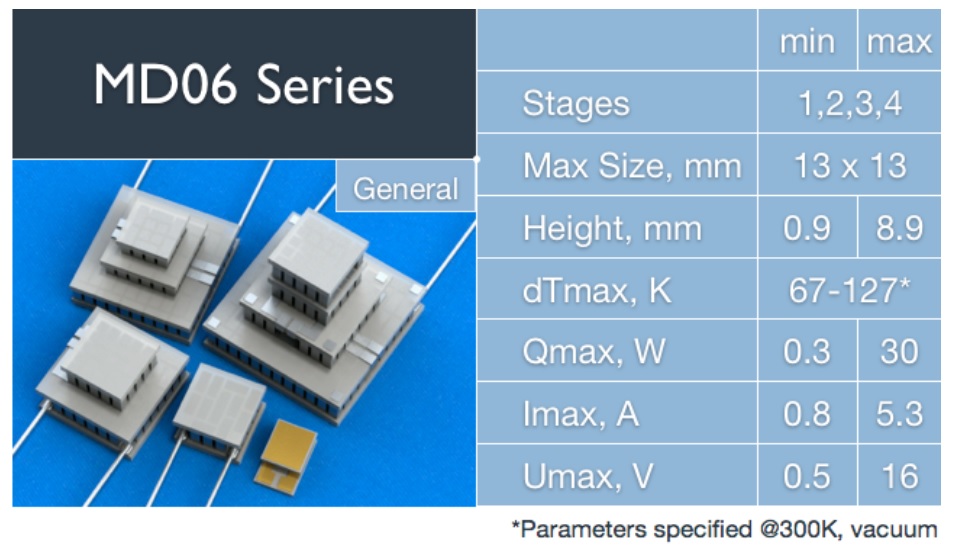

MD06

|

|

3MDC

|

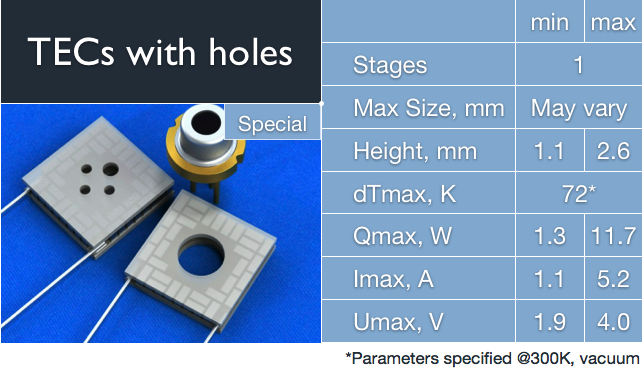

with holes

|

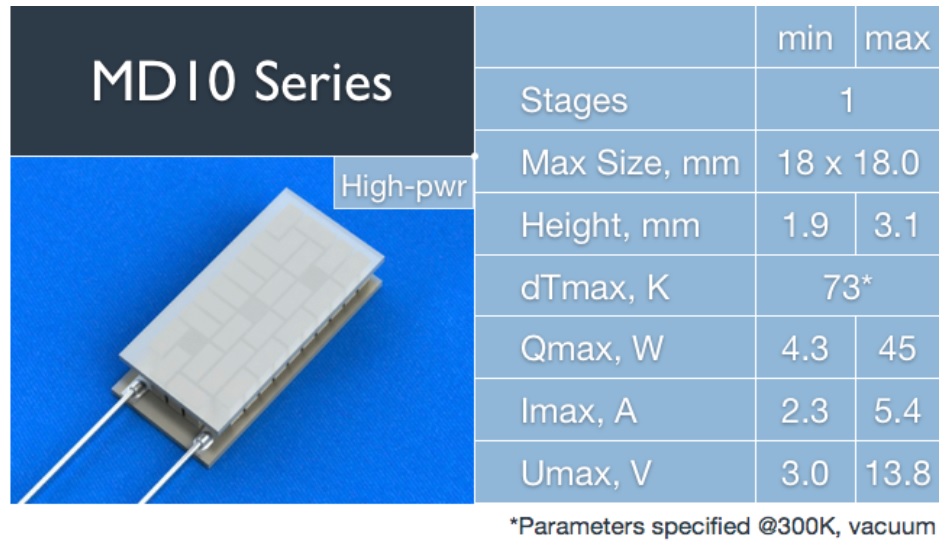

MD10

|

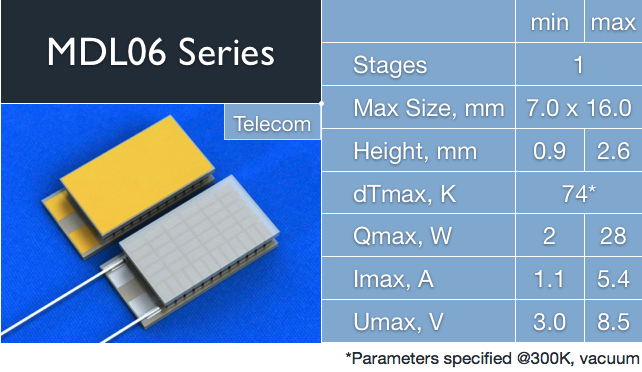

MDL06

|

MD03

|

MDX04

|

MDX06

|

|

|

|

|

MD02

|

MX

|

||

Thermoelectric coolers of MC Series

Thermoelectric coolers of MD Series

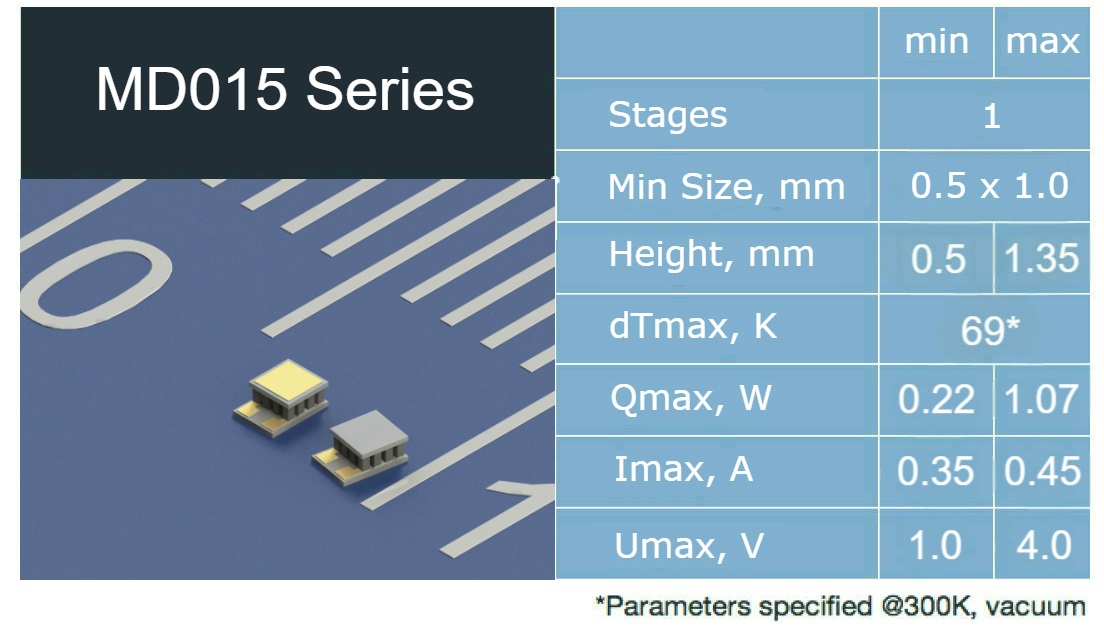

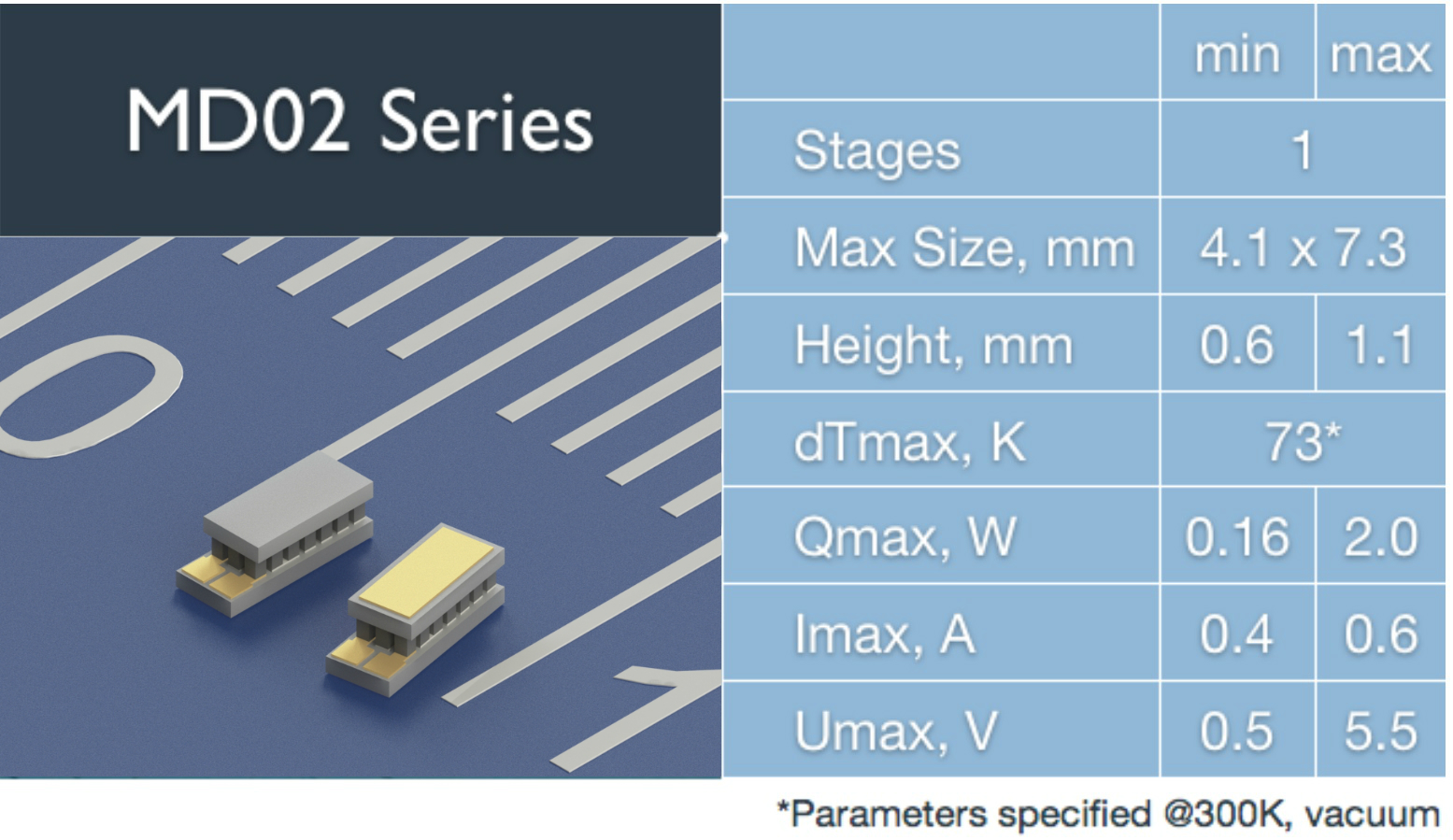

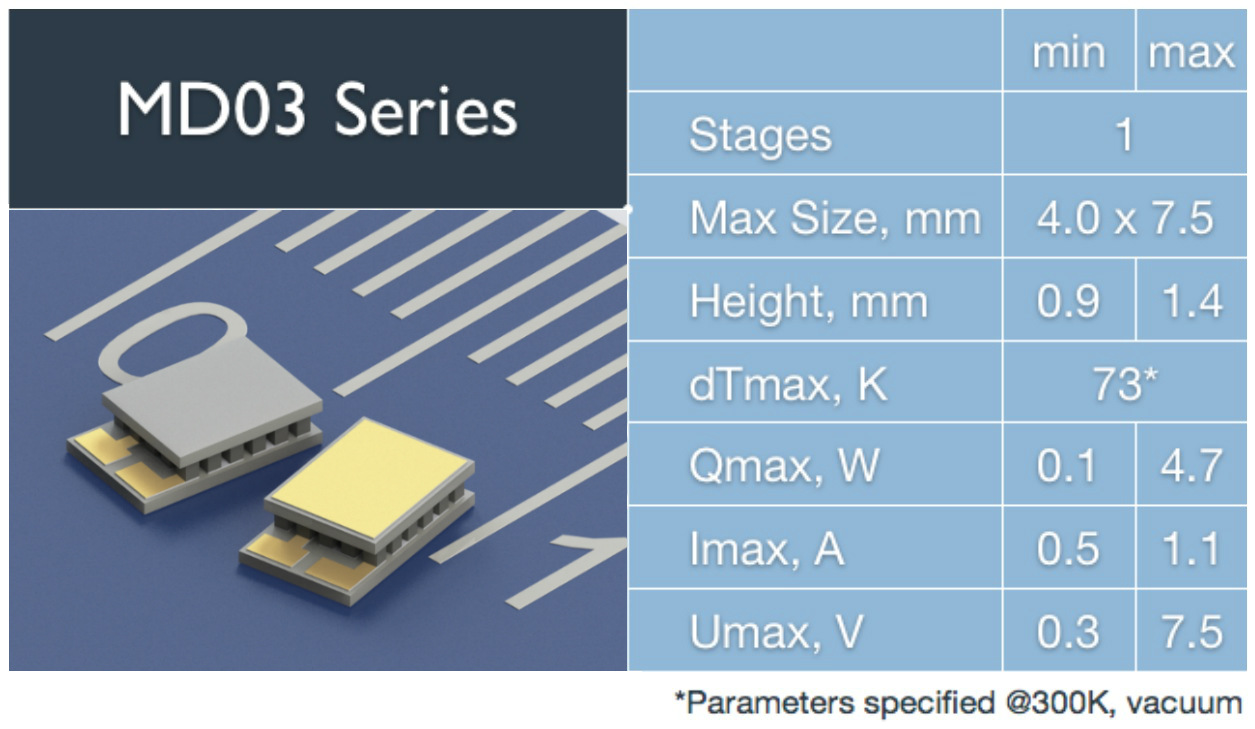

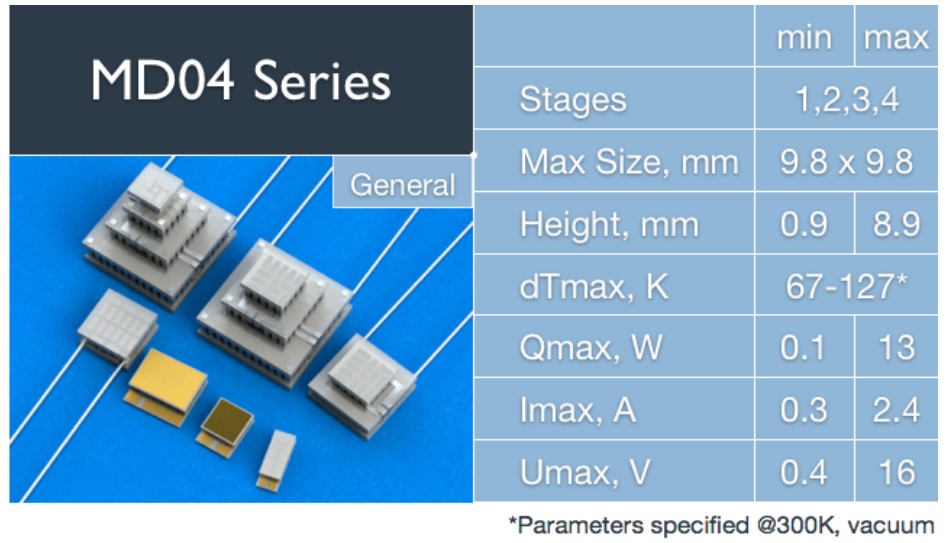

Thermoelectric cooler of MD Series are based on RMT HD pellets technologies with high density pellets placement. MD04, MD06 and MD10 Series are based on HD technology with about 250 pellets per 1 cm2 density. MD03 Series of low current TECs is developed specially for cooled TOSA applications and is based in RMT advanced HD technology (more than 400 pellets per 1 cm2). MD02 Series has a range of TEC with 1100 pellets per 1 cm2. MD015 Series has a unique combination of a miniature cross section of pellets and a distance of 100 μm between them, which allows the density of 1600 pellets per 1 cm2. Each TEC Series has its own advantages depending on application conditions and requirements.

MD Series thermoelectric coolers are based on RMT high-density pellets placement technology. The distance between elements is reduced, comparing with regular technology TECs. This allows to reduce the size of thermoelectric cooler keeping the same performance as regular type, or to increase the cooling capacity up to 100% with the same size as regular TEC has. There are six MD Series available: MD015, MD02, MD03, MD04, MD06 and MD10. The difference between series is in internal pellets cross section, performance parameters range and overall dimensions.

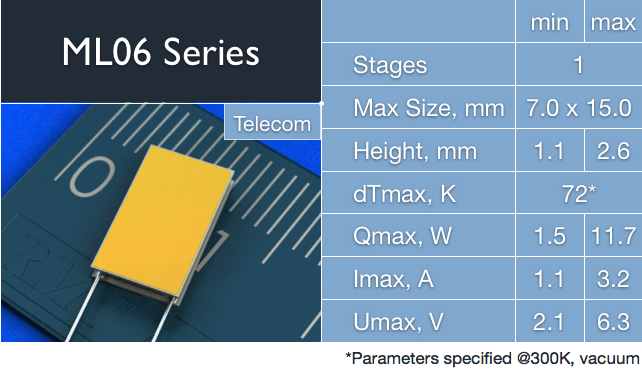

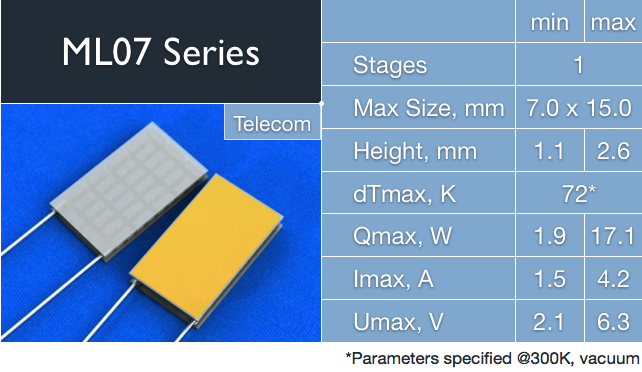

Thermoelectric coolers of ML Series

|

|

|

There are two ML thermoelectric coolers Series - ML06 and ML07. Both have the same dimensions and are very common for WDM applications in standard “Butterfly” or DIL packages. The main difference between ML06 and ML07 Series is in internal elements cross-section. ML07 thermoelectric coolers are more powerful in terms of cooling capacity and may be more optimal for applications with high heatload. ML06 Series is the standard thermoelectric coolers Series for telecom industry. In terms of geometry and applied materials both Series are equal, qualified by Telcordia GR-468 Standard and RoHS compliant.

Thermoelectric coolers of MDL06 Series

Thermoelectric coolers with holes

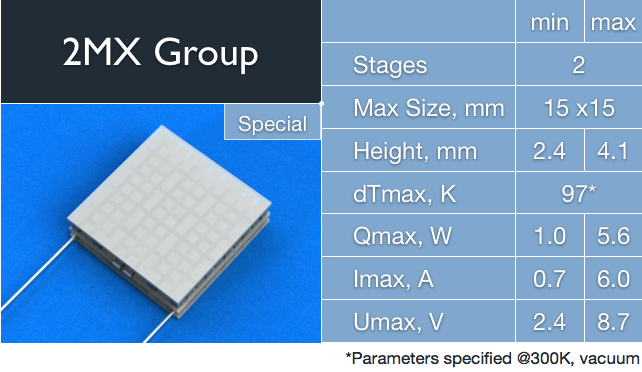

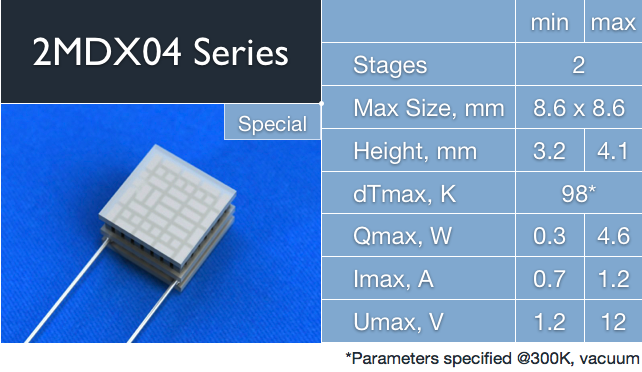

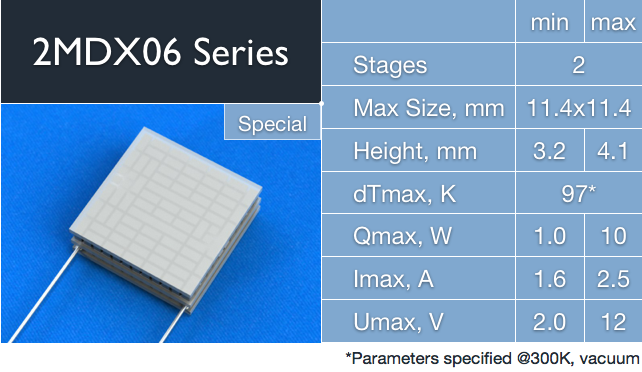

Thermoelectric coolers of 2MDX Series

|

|

|

MDX Series TECs are developed by RMT separately to general 2-stage thermoelectric coolers. MDX TECs have 2 stages and with the same dimensions for hot and cold sides, different to typical pyramidal shape of multistage TE coolers. There are two Series - MDX04 and MDX06. The difference is in internal elements cross-section and as a result - performance parameters and overall dimensions. The optimal balance of parameters and additional flexibility in TEC height variations by ceramics thickness allow to replace single-stage TE coolers in sensing applications keeping the same geometry.

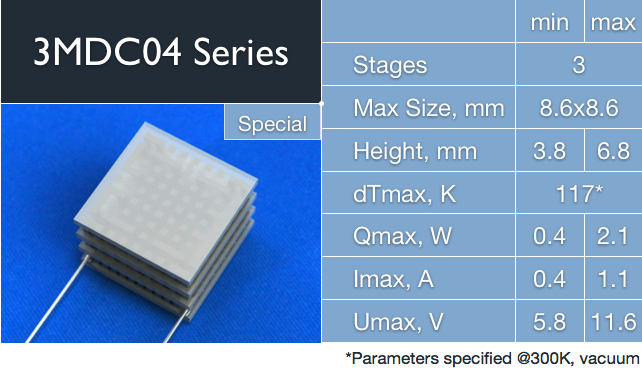

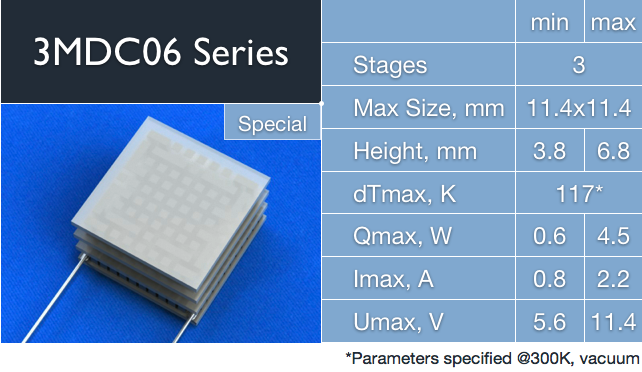

Thermoelectric coolers of 3MDC Series

|

|

|

3MDC Series consist of 3-stage thermoelectric coolers with specially enlarged cold side area. 3MDC 3-stage thermoelectric coolers combine the standard RMT assembly technology and HD pellets placement technologies. The result is large cold ceramics area with the same size of TEC hot side. This is a key feature of 3MDC TE coolers, comparing with standard multistage TECs that have a pyramidal shape. 3MDC TECs are optimal for detector applications. 3MDC unique TEC shape also allows to form TE cooler arrays. New 3MDC TECs have up to 60% higher cooling capacity, comparing with typical solutions of the same size available on the market.

Thermoelectric coolers of MX Group

Custom Designed Modules

Custom designed TE modules are available according to demanded specifications.

Please, contact us - info@rmtltd.ru