Application Tips

Thermoelectric cooler (TEC) is a semiconductor device which is characterized by unique heat pump performance with high efficiency, compactness and durability. The unique ability of TECs to heat and cool, permits them to lower temperature of an object below ambient as well as to stabilize temperature of objects in widely varying ambient conditions.

Here we mention some application tips that can help in optimal use of TECs.

Mounting

Power Supply

Environment

Handling

Heat Dissipation

Reference Data

Brief Summary

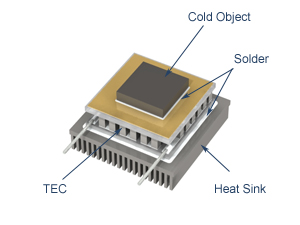

MOUNTING BY SOLDERING

-

-

The TEC is soldered by a soft solder to a heat-conducting header, and a cooled object is soldered by a similar way on the cold side of the TE module. The thermal contact and mechanical durability is provided by the used solder.

Advantages

The method provide good mechanical durability, good thermal contact between the surfaces. It is suitable for vacuum applications as it does not cause outgassing. No need for additional space as in case of mechanical mounting. Partial disassembling is possible.

Application

It is the main mounting method for single- and multistage micromodules. For large modules it is limited because a risk of mechanical strain owing to a difference of thermal expansions of contacting surfaces.

Restrictions

Is not applicable for large size TECs (more than 15-20 mm). Professional personnel is required for the mounting method. There is a risk to damage TECs during procedures. TEC must have metallized surfaces suitable for soldering.

Procedure

- Clean and degrease the heat sink surface and remove any heavy oxidation. Make sure that there are no burrs, chips, or other foreign material in the module mounting area.

- Pre-tin the heat sink surface in the module mounting area with the appropriate solder.

Note: The selected solder must have a melting point lower than or equal to the rated maximum processing temperature of the TE device being installed. When tinning the heat sink with solder, the heat sink's temperature should be just high enough so that the solder will melt but in no case should the temperature be raised more than the maximum value specified for the TEC.

- Apply soldering flux to the TE module's hot side and place the module on the pre-tinned area of the heat sink. Allow the module to «float» in the solder pool and apply a back and forth turning motion on the module to facilitate solder tinning of the module surface.

Note: A tendency for the module to drag on the solder surface rather than to float is an indication that the amount of solder is insufficient. In the case, remove the module and add more solder to the heat sink.

- After several seconds the module surface should be tinned satisfactorily. Clamp or weight load the module in the desired position, remove the heat sink from the heat source, and allow the assembly to cool. When sufficiently cooled, degrease the assembly to remove flux residue.

- Rinse mount with TEC in hot water, then scrub with cleaning solution and rinse again with hot water, brushing away any excess flux residue around the pins. Wash with hot water and dry with forced air. To insure complete removal of moisture, dry the entire assembly in an oven for 30 minutes at 60°C.