Application Tips

Thermoelectric cooler (TEC) is a semiconductor device which is characterized by unique heat pump performance with high efficiency, compactness and durability. The unique ability of TECs to heat and cool, permits them to lower temperature of an object below ambient as well as to stabilize temperature of objects in widely varying ambient conditions.

Here we mention some application tips that can help in optimal use of TECs.

Mounting

Power Supply

Environment

Handling

Heat Dissipation

Reference Data

Brief Summary

MECHANICAL MOUNTING

-

-

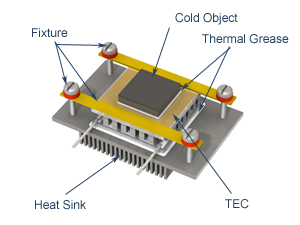

TEC module is placed between two heat exchangers (plates) fixed by screws. For good thermal conductance the clearances between the plates are filled with thermal conductive grease or heat-conducting gasket.

Application

The method is widely applied for mounting of large single-stage TE modules and when permanent TEC mounting bonding is not desired.

Advantages

Advantages of the mechanical method of installation are a possibility to disassemble of the construction and, consequently, maintainability of a design.

Restrictions

Mechanical mounting is not applied to most of TEC micromodules applications as the mechanical installation demands extra space. Passive heat fluxes through the elements of fixtures reduce TEC performance, which is crucial for micromodules efficiency, especially in case of multi-stage TECs.

Procedure

- Prepare heat exchanger, cold exchanger and TEC surfaces. All surfaces must be not more than 0.03 mm of flatness.

- Locate bolt holes in your assembly so that they are at opposite sides of the cooler. The bolt holes should be in the same plane line as the heat sink fins to minimize any bowing that might occur.

- The recommended hardware that should be used are 4-40" or similar screws, not more. Bellville or split lock type washers as well as a fiber insulated washer must be applied to insulate the screw head from heat exchange.

- Clean and prepare mounting surfaces, with ethanol, acetone or general use solvents. Remove all burrs.

- Apply a thin 0.05mm layer thermal grease to the hot side of the TEC.

- Place the TEC on the heat sink and rotate the TEC back and forth, squeezing out the excess thermal grease until resistance is felt.

- Repeat two previous steps (if cold side mounting is also mechanical) and rotate cold exchanger back and forth, squeezing out the thermal grease excess.

- Torque screws. Be careful to apply torque by small increments, alternating between screws.