Print version

Back to Company News

Hi-TEC - High Performance Thermoelectric Coolers for High Heat Load applications

Mar 11, 2010

RMT Ltd introduces thermoelectric coolers, optimized for high-power LD applications in HHL form-factor. High-performance thermoelectric coolers of MC06 and MX06 Series with cooling capacity starting from 28W and higher provide significantly better cooling performance than any standard solutions available on the market.

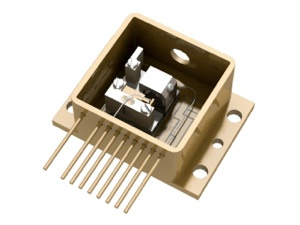

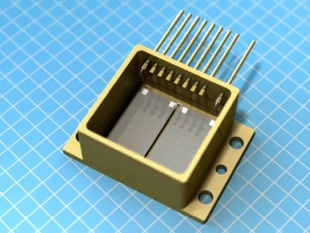

Among all modern tendencies for miniaturization in semiconductor laser and optoelectronics applications, there is an area where relatively large solutions and high-power solutions are required. High-power solid-state CW lasers widely used in medical and industrial applications. High output LD power requires the improved thermal management. For applications with LD output power of 2W and higher there is a typical packaging solution based on HHL package. HHL (High Heat Load) packages were designed to provide optimal LD thermal management for high-power applications. This is the largest industrial standard package available. Windowed and fibered HHL packages are typical as a standard packaging solution for solid-state laser pumping in medical and industrial application areas like: materials processing, medical and dental therapeutics, graphic arts, eye-safe applications and others.

Laser diode inside HHL requires an appropriate temperature stabilization. The integrated thermoelectric cooler is a typical solution for such applications. However, most of standard thermoelectric coolers, that are suitable for installing in HHL package, have 10-15W of max cooling capacity. Meanwhile CW lasers demands are growing, LD output power is being increased by manufacturers, and the amount of heat to be dissipatedВ grows as well. When it is required to dissipate for instance 20-30W, typical thermoelectric coolers are not suitable. Most of standard solutions with enough cooling capacity for it have 30x30mm or larger dimensions, they are not suitable for integrating in HHL package. In this case manufacturers apply external solutions for temperature stabilizationВ like water cooling or air fans. But such solutions have limits for temperature regulating speed, size, power consumption and max cooling temperature level achieved.

Laser diode inside HHL requires an appropriate temperature stabilization. The integrated thermoelectric cooler is a typical solution for such applications. However, most of standard thermoelectric coolers, that are suitable for installing in HHL package, have 10-15W of max cooling capacity. Meanwhile CW lasers demands are growing, LD output power is being increased by manufacturers, and the amount of heat to be dissipatedВ grows as well. When it is required to dissipate for instance 20-30W, typical thermoelectric coolers are not suitable. Most of standard solutions with enough cooling capacity for it have 30x30mm or larger dimensions, they are not suitable for integrating in HHL package. In this case manufacturers apply external solutions for temperature stabilizationВ like water cooling or air fans. But such solutions have limits for temperature regulating speed, size, power consumption and max cooling temperature level achieved.

Now the solution with miniature high performance integrated thermoelectric cooling is availbale. The key feature is in high-performance thermoelectric coolers with high cooling capacity, which are suitable for HHL package applications by size. RMT Ltd provides three groups of high-performance TECs for HHL package applications available: standard, enhanced and extreme. Standard solutions are based on 1MC06-126-xx and 1MC06-142-xx RMT types.

В

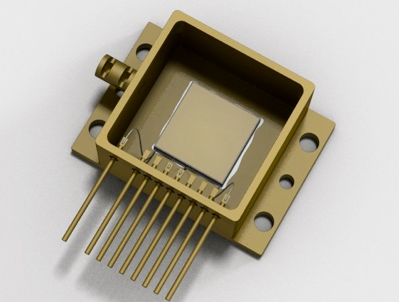

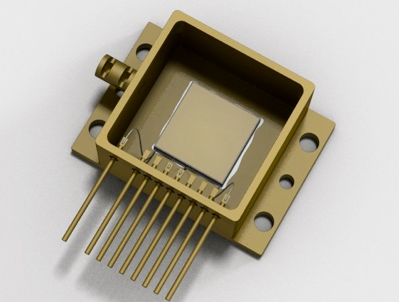

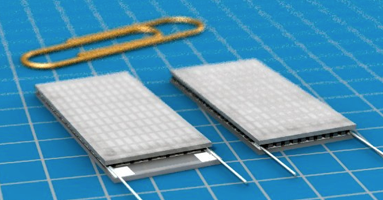

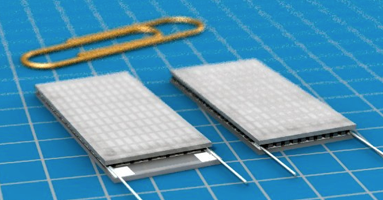

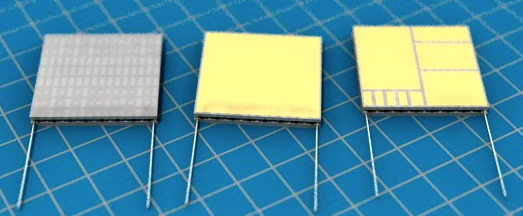

1MC06-142-03 (left) and 1MC06-142-05 TEC types for HHL applications

soec

For applications with voltage limits of power supply there are alternate TE coolers with the same dimensions and cooling capacity, but another Imax/Umax combination from MX06 Series.

spec

The enhanced solutions are based on standard 1MC06 and 1MX06 TECs with reduced pellet height. Pellet is the BiTe element inside thermoelectric cooler. The reducing of pellet height increases the cooling capacity of thermoelectric cooler. The result of pellet increasing for standard TECs is about 60% cooling capacity increasing. Thus, the max cooling capacity of 1MC06-142-03 is 50W, significantly more than any typical solution, available on the market.

spec

The increased cooling capacity allows to use thermoelectric coolers in that high-power LD applications, where it was not possible before, because of consumer TECs Qmax limit. Also large cooling capacity reserve allows TEC to operate with more optimal C.O.P. With the increased cooling capacity it is possible to get TEC C.O.P close or even higher than 1, which means that TEC electrical power consumption is less than pumped heat value.

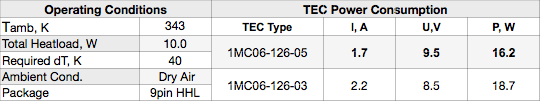

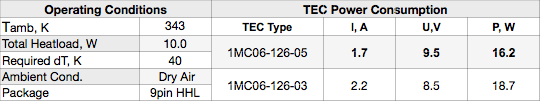

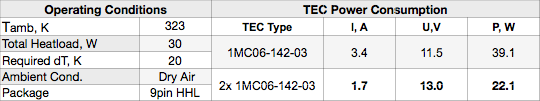

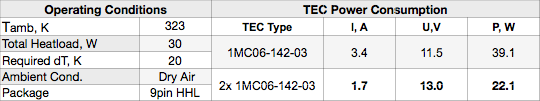

Example #1 - TECs performance in sample operating mode, standard version is preferable

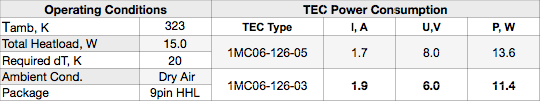

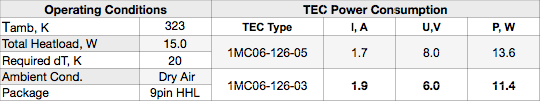

Example #2 - TECs performance in sample operating mode with optimal C.O.P., enhanced version is preferable

Laser diode inside HHL requires an appropriate temperature stabilization. The integrated thermoelectric cooler is a typical solution for such applications. However, most of standard thermoelectric coolers, that are suitable for installing in HHL package, have 10-15W of max cooling capacity. Meanwhile CW lasers demands are growing, LD output power is being increased by manufacturers, and the amount of heat to be dissipatedВ grows as well. When it is required to dissipate for instance 20-30W, typical thermoelectric coolers are not suitable. Most of standard solutions with enough cooling capacity for it have 30x30mm or larger dimensions, they are not suitable for integrating in HHL package. In this case manufacturers apply external solutions for temperature stabilizationВ like water cooling or air fans. But such solutions have limits for temperature regulating speed, size, power consumption and max cooling temperature level achieved.

Laser diode inside HHL requires an appropriate temperature stabilization. The integrated thermoelectric cooler is a typical solution for such applications. However, most of standard thermoelectric coolers, that are suitable for installing in HHL package, have 10-15W of max cooling capacity. Meanwhile CW lasers demands are growing, LD output power is being increased by manufacturers, and the amount of heat to be dissipatedВ grows as well. When it is required to dissipate for instance 20-30W, typical thermoelectric coolers are not suitable. Most of standard solutions with enough cooling capacity for it have 30x30mm or larger dimensions, they are not suitable for integrating in HHL package. In this case manufacturers apply external solutions for temperature stabilizationВ like water cooling or air fans. But such solutions have limits for temperature regulating speed, size, power consumption and max cooling temperature level achieved.

Now the solution with miniature high performance integrated thermoelectric cooling is availbale. The key feature is in high-performance thermoelectric coolers with high cooling capacity, which are suitable for HHL package applications by size. RMT Ltd provides three groups of high-performance TECs for HHL package applications available: standard, enhanced and extreme. Standard solutions are based on 1MC06-126-xx and 1MC06-142-xx RMT types.

В

1MC06-142-03 (left) and 1MC06-142-05 TEC types for HHL applications

For applications with voltage limits of power supply there are alternate TE coolers with the same dimensions and cooling capacity, but another Imax/Umax combination from MX06 Series.

spec

The enhanced solutions are based on standard 1MC06 and 1MX06 TECs with reduced pellet height. Pellet is the BiTe element inside thermoelectric cooler. The reducing of pellet height increases the cooling capacity of thermoelectric cooler. The result of pellet increasing for standard TECs is about 60% cooling capacity increasing. Thus, the max cooling capacity of 1MC06-142-03 is 50W, significantly more than any typical solution, available on the market.

spec

The increased cooling capacity allows to use thermoelectric coolers in that high-power LD applications, where it was not possible before, because of consumer TECs Qmax limit. Also large cooling capacity reserve allows TEC to operate with more optimal C.O.P. With the increased cooling capacity it is possible to get TEC C.O.P close or even higher than 1, which means that TEC electrical power consumption is less than pumped heat value.

Example #1 - TECs performance in sample operating mode, standard version is preferable

Example #2 - TECs performance in sample operating mode with optimal C.O.P., enhanced version is preferable

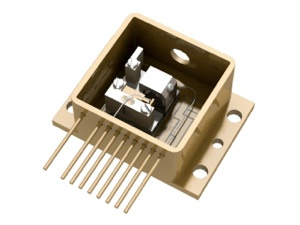

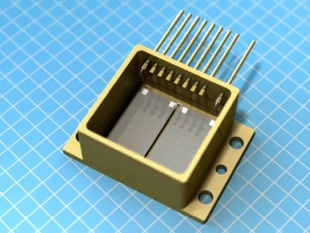

Finally, the extreme cooling solution is available, based on two enhanced 1MC06-142-03 TEC installed in HHL package and connected in serial. 1MC06-142-03 type has 12x24mm dimensions. Two of them, being installed in HHL, form the operating area of 24x24mm - typical size for standard thermoelectric coolers. The summary max cooling capacity is 100W, extreme value for lasers in HHL package.

In most cases there is no need in operating at such Qmax. But large cooling capacity solution provides the most optimal C.O.P. in operating mode. For example 2x1MC06-142-03 TECs in HHL will require 22W of electrical power to pump 30W from LD and provide dT=20K (stabilizing of LD at 30C from 50C ambient) in dry air.

Example #3 - TECs performance in sample operating mode high heatload, extreme version is preferable

Example #3 - TECs performance in sample operating mode high heatload, extreme version is preferable

The appropriate heatsink is required anyway to spread the pumped heat from HHL header - thermoelectric cooler operates as a heat pump. The advantage of high-performance thermoelectric coolers for LD in HHL packages is in possibility to pump large heat amounts with better C.O.P., fast and effective temperature regulating, higher cooling temperature level to achieve and expanded temperature ranges in operating mode.

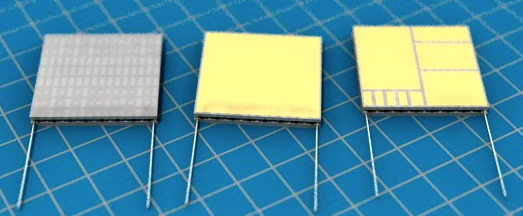

For optimization of assembling process TE cooler cold side ceramics can be with different surface solutions - blank ceramics for gluing of mounting with thermal adhesives or Au plated ceramics is the universal solution, optimal for soldering. Additionally customized Au patterns can be provided by request.

Different ceramics surfaces are available by request

Different ceramics surfaces are available by request

RMT Ltd provides thermoelectric coolers separately or assembled in standard or customer provided HHL packages.